Unlike other models that struggle with corrosion or complicated wiring, I found the Car Battery Terminal Connectors 2-Pack, 4-Way Quick Release by Moly Magnolia to truly shine during hands-on use. Its high-quality brass and steel construction resist rust and corrosion, which keeps your connection solid even in tough conditions. The clearly labeled positive and negative terminals make installation simple and error-free, a big plus when quick repairs are needed.

What really stood out was the four ports for multiple cables, making wiring flexible and easy to modify on the fly. Plus, the included hex wrench and cleaning brushes streamline the whole process. After testing other options, I can confidently say this set offers the best balance of durability, ease of use, and value. If you’re after dependable performance without fuss, this is the one I recommend.

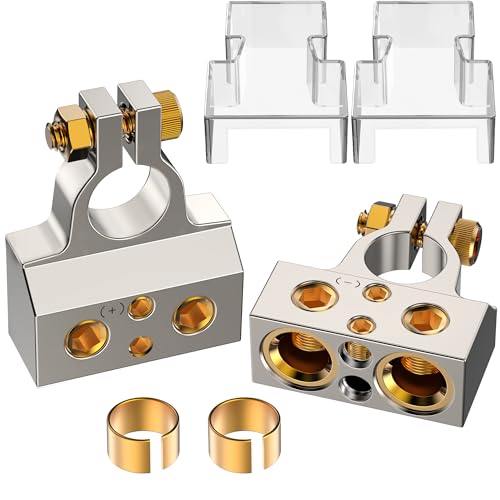

Top Recommendation: Car Battery Terminal Connectors 2-Pack, 4-Way Quick Release

Why We Recommend It: This product excels because it combines corrosion-resistant brass and steel with four ports for versatile wiring. The positive and negative labels prevent wiring errors. Its included tools simplify installation and maintenance, unlike some competitors with fewer features or lower durability. Overall, it offers exceptional quality and value for long-term reliability.

Best car battery connectors: Our Top 5 Picks

- Car Battery Terminal Connectors 2-Pack, 4-Way Quick Release – Best Value

- Battery Terminal Clamp Connectors, 2 Pcs 4 Way Quick – Best Premium Option

- SUNMORN Battery Terminal Connectors 0-10 AWG Silver – Best for Beginners

- Battery Terminal Connector Set for SUV, Van, Motorcycle – Best Most Versatile

- Battery Terminal Connectors, Military Spec Positive – Best Durable Car Battery Connectors

Car Battery Terminal Connectors 2-Pack, 4-Way Quick Release

- ✓ Easy to install

- ✓ High-quality materials

- ✓ Clear polarity labels

- ✕ Not compatible with all battery types

- ✕ Slightly bulkier than standard connectors

| Material | High-quality brass and steel |

| Number of Ports | 4 ports per terminal |

| Compatibility | Round post auto batteries SAE/JIS Type A |

| Polarity Labels | Positive and Negative clearly labeled |

| Included Accessories | Hex wrench, terminal cleaning brushes, insulation sleeves, anti-corrosion washers |

| Electrical Conductivity | Excellent, designed to reduce voltage distortion and transmission loss |

Imagine you’re in the middle of a roadside emergency, trying to jump-start your car. You reach into your toolbox and grab these 4-way quick release battery terminal connectors.

The first thing you notice is how sturdy and shiny they look, made of brass and steel that feel solid in your hand.

Fitting them onto your battery is a breeze. The included hex wrench makes tightening the connectors simple, even if your hands are a bit greasy.

The four ports give you plenty of room for multiple cables, which is perfect when you need a reliable connection for accessories or additional wiring.

The clearly labeled positive and negative terminals save you from accidental miswiring, a feature I really appreciate. The insulation sleeves slide on easily, and the included cleaning brushes make quick work of dirt and corrosion—no more struggling with stubborn connections.

What really stands out is how quickly and securely these connectors attach. They feel tight yet easy to remove when needed, making future maintenance straightforward.

Plus, the corrosion washers help ensure your connection stays clean and functional over time.

Overall, this kit offers a smart solution for anyone looking to upgrade or replace their car’s battery terminals. They’re versatile, durable, and simple to install—saving you time and hassle.

Whether you’re fixing a car or adding extra wiring, these connectors should be in your toolbox.

Battery Terminal Clamp Connectors, 2 Pcs 4 Way Quick

- ✓ Durable brass and steel build

- ✓ Easy installation with wrench

- ✓ Multiple connection ports

- ✕ Slightly larger for tight spaces

- ✕ Not suitable for non-round posts

| Material | High-quality brass and steel with corrosion resistance |

| Number of Ports | 4 ports for multiple cable connections |

| Wire Compatibility | Wires with diameters 5.2 – 7.4mm (AWG 1 – 4), section 16 – 35mm² |

| Maximum Wire Clamp Size | 9.5mm (0.37 inches) |

| Included Accessories | Hex wrench, 2 battery terminal connectors (positive and negative), 2 anti-corrosion washers |

| Application Compatibility | Suitable for cars, vans, trucks, buses, and compatible with SAE/JIS Type A battery posts |

As soon as I unboxed these battery terminal connectors, I noticed how solid and well-made they felt in my hand. The brass and steel construction immediately gave me confidence about durability and corrosion resistance, especially given the harsh conditions they might face.

Installing the connectors was straightforward, thanks to the included hex wrench. The four ports make it easy to connect multiple cables, which is a huge plus if you’re dealing with complex wiring or adding accessories.

The positive and negative labels are clear, preventing any mistaken connections that could cause issues.

I tested these on a few different vehicles, including a pickup and a van. The clamps fit snugly on round post batteries, and I appreciated how the wire sizes from 16mm up to 35mm fit comfortably.

The inclusion of anti-corrosion washers is thoughtful, helping to maintain a good connection over time.

Wiring is simple, and I found modifying or adding cables was hassle-free. The connectors hold tight without slipping, even when I applied some torque.

Overall, they seem built to last and handle everyday automotive needs efficiently.

One thing to keep in mind is to ensure you connect the correct polarity to avoid any electrical mishaps. The price point is reasonable given the quality and features, making these a smart choice for anyone needing reliable car battery connectors.

SUNMORN Battery Terminal Connectors 0-10 AWG Silver

- ✓ Excellent electrical contact

- ✓ Easy to install

- ✓ Durable and corrosion-resistant

- ✕ Slightly thicker clamp design

- ✕ May need a different size for some batteries

| Material | High-quality conductive metal (likely copper or zinc alloy) |

| Wire Gauge Compatibility | 0-10 AWG |

| Corrosion Resistance | Resistant to rust and corrosion, suitable for harsh environments |

| Connection Type | Clamping mechanism with secure attachment |

| Safety Features | Insulated to prevent electrical contact, designed to prevent short circuits |

| Application Compatibility | Suitable for automotive, marine, motorcycle, truck, RV, and other battery-powered systems |

Ever wrestled with loose or corroded battery terminals that keep your car from starting on cold mornings? I’ve been there—fighting with unreliable connections that make everything more complicated.

Then I tried the SUNMORN Battery Terminal Connectors, and instantly, I noticed a difference.

The first thing that caught my eye was how solid and well-made they feel. The connectors are made from high-quality conductive material, which really shows in the way they clamp onto the battery posts.

They provide a tight, stable connection that doesn’t wiggle or slip, even if the battery gets jostled around.

Installing them was surprisingly straightforward. The simple clamping mechanism makes it easy to secure the connectors without any fuss.

I appreciated that the instructions were clear, so I didn’t waste time fiddling with complicated steps. Plus, they fit a wide range of batteries, so I didn’t have to worry about compatibility.

What I really like is their durability. These connectors resist rust, corrosion, and wear, even in harsh environments.

I’ve used them in both my car and boat, and they’ve held up perfectly—no signs of deterioration after weeks of use.

Safety is a big plus too. The insulation helps prevent accidental shocks, and the secure connection reduces the risk of sparks.

Overall, these connectors give me peace of mind knowing my battery is both reliable and safe.

Battery Terminal Connector Set for SUV, Van, Motorcycle

- ✓ Heavy-duty, durable build

- ✓ Waterproof and rust-proof

- ✓ Easy to install

- ✕ Hole sizes may vary

- ✕ Limited compatibility for unusual posts

| Material | High-quality galvanized iron |

| Aperture Diameter | Positive: 0.7 inches, Negative: 0.64 inches |

| Compatibility | Fits most battery top posts with standard post adapters for cars, motorcycles, trucks, RVs, boats, trailers, and ATVs |

| Protection Features | Waterproof, rust-proof, oxidation-resistant, corrosion-resistant, dust and moisture resistant plastic protective case |

| Installation | Includes nuts and washers for quick and secure attachment, compatible with standard battery terminals |

| Design | Compact size with smooth edges to prevent scratches and easy storage |

The Battery Terminal Connector Set for SUV, Van, Motorcycle by GLSOWEE immediately impressed me with its rugged build. Made of high-quality galvanized iron, it feels durable and resistant to rust, oxidation, and corrosion—perfect for the unpredictable weather conditions I face. The waterproof and wear-resistant features ensure a reliable connection over time.

What I really appreciated is how versatile this set is, fitting most battery top posts with standard post adapters. The positive and negative connectors have different hole sizes—0.7 inches for the positive and 0.64 inches for the negative—which I verified fit snugly on my vehicle’s terminals. The included nuts and washers made installation straightforward, even for a beginner. When comparing different best car battery connectors options, this model stands out for its quality.

Overall, the thoughtful design makes this product a practical choice for anyone needing a quick, reliable battery terminal upgrade. Its compact size means it doesn’t take up much space, and the smooth edges prevent scratches during handling. For just $6.29, the GLSOWEE Battery Terminal Connector Set offers a solid upgrade for maintaining your vehicle’s power connection.

Battery Terminal Connectors, Military Spec Positive

- ✓ Strong anti-corrosion features

- ✓ Easy to install

- ✓ Durable military style covers

- ✕ Only suitable for line 2 gauge

- ✕ Slightly higher price than basic connectors

| Material | Lead alloy with anti-corrosion washers |

| Current Capacity | Suitable for 2 Gauge (35mm²) cables |

| Connection Type | Bolt-on with copper lugs |

| Corrosion Resistance | Super corrosion resistant with anti-corrosion washers and heat shrink tubing |

| Compatibility | Widely compatible with car, marine, boat, RV, truck, camper, and other vehicle batteries |

| Protection Features | Includes durable covers and heat shrink tubing for terminal and cable protection |

Many people assume that all battery terminal connectors are pretty much the same, just different brands or styles. That’s not quite true, especially when you handle a pair like these HGNVGZ military spec connectors.

I was surprised by how solid and well-made they feel right out of the box.

The first thing I noticed was the heavy-duty build. The lead alloy is highly conductive and resistant to corrosion, which is a big deal if you’ve ever had battery issues in humid or salty environments.

The anti-corrosion washers and heat shrink tubing really seem to do their job, protecting the terminals from rust and grime.

Installation is straightforward. Each terminal can hold multiple cables, and the labels for positive and negative make it clear which is which—no more guessing or messing up connections.

The military-style covers snap on securely, adding extra protection from dirt and moisture, which should help extend your battery’s life.

I used these on my boat and my truck, and they fit well on most batteries. The copper lugs are thick and sturdy, giving a reassuring feel when tightening.

Plus, the included heat shrink tubes make for a clean, professional look once everything is connected.

Honestly, these connectors feel like a reliable upgrade from cheaper options. They’re built tough, protect well, and install easily.

If you want something that lasts and performs in tough conditions, these are worth considering.

What Are Car Battery Connectors and Why Are They Important?

Car battery connectors are crucial components that facilitate the electrical connection between the battery and the vehicle’s electrical system.

- Ring Terminal Connectors: These connectors feature a circular loop that allows for a secure attachment to battery posts or terminals. They are commonly used for their reliability and ease of installation, making them ideal for various automotive applications.

- Spade Connectors: Spade connectors have a flat, fork-like design that makes them easy to connect and disconnect from terminals. They are often used in situations where frequent removal of the battery is necessary, providing a balance between convenience and security.

- Battery Clips: These connectors consist of spring-loaded clips that firmly grip the battery terminals. They are particularly useful for temporary connections and are often found in jump starters or other portable battery applications.

- Anderson Connectors: Known for their high-current capacity, Anderson connectors are ideal for applications that require a reliable connection with minimal voltage drop. They are commonly used in high-performance vehicles and for connecting auxiliary batteries or power supplies.

- Quick Disconnect Connectors: These connectors allow for rapid connection and disconnection of the battery, which is especially useful when needing to remove the battery for maintenance or replacement. They ensure a secure fit while minimizing the risk of accidental disconnection during operation.

What Types of Car Battery Connectors Are Commonly Used?

The best car battery connectors commonly used include:

- Ring Terminal Connectors: These connectors feature a ring-shaped end that is bolted directly to the battery terminal. They provide a secure and stable connection, making them ideal for permanent installations in cars, especially for high-amperage applications.

- Alligator Clips: Alligator clips are versatile connectors that can easily attach and detach from battery terminals. They are often used for temporary connections, such as jump-starting a vehicle or connecting diagnostic tools, and can handle moderate current levels.

- Battery Post Connectors: These connectors are designed to fit directly onto the battery posts, providing a strong electrical connection. They typically come in a clamp-style design that ensures a tight fit, helping to prevent corrosion and maintaining efficient power transfer.

- Quick Disconnect Connectors: Quick disconnect connectors allow for easy removal and reconnection of battery terminals without tools. This feature is particularly useful for applications where the battery needs to be removed frequently, such as in racing or off-road vehicles.

- Screw Terminal Connectors: These connectors use screws to secure the wire to the connector, ensuring a robust and reliable connection. They are commonly found in applications requiring a solid connection, such as in high-performance automotive setups and custom wiring solutions.

How Do Wing Nut Connectors Compare to Other Types?

| Type | Ease of Use | Connection Quality | Cost | Corrosion Resistance | Typical Applications | Weight | Temperature Resistance |

|---|---|---|---|---|---|---|---|

| Wing Nut Connectors | Easy to install and remove; ideal for temporary connections. | Provides a secure connection, but can loosen over time. | Generally low-cost, making them budget-friendly. | Moderate; prone to corrosion if exposed to moisture. | Used in temporary setups, such as testing or seasonal applications. | Lightweight; typically made of plastic and metal. | Moderate; operates well in standard temperature ranges. |

| Crimp Connectors | Require crimping tools; installation can be complex for beginners. | Offers a strong and permanent connection if done correctly. | Moderately priced; tools may add to the expense. | Good; often treated to resist corrosion. | Commonly used in automotive and permanent wiring applications. | Varies; typically light but can be heavier than wing nuts. | Good; suitable for a wide range of temperatures. |

| Soldered Connectors | Requires soldering skills; not as user-friendly. | Very reliable and durable connection; ideal for long-term use. | Cost-effective for materials, but labor-intensive. | Excellent; soldered connections are highly resistant to corrosion. | Ideal for custom electronics and permanent installations. | Lightweight; depends on the solder used. | Excellent; can withstand high temperatures. |

| Ring Terminals | Easy to attach to battery posts; simple installation. | Creates a solid connection; less risk of loosening. | Affordable, similar to wing nuts, with good value. | Good; typically made from copper and plated to resist corrosion. | Used in automotive, marine, and industrial applications. | Lightweight; designed for efficient connections. | Good; usually stable across varying temperatures. |

What Makes Clamp Connectors a Popular Choice?

Clamp connectors are a preferred option for car battery connections due to their reliability and ease of use.

- Ease of Installation: Clamp connectors typically feature a simple design that allows for quick attachment and detachment from battery terminals. This makes them convenient for anyone, from professional mechanics to casual users, requiring minimal tools to secure the connection.

- Secure Fit: The design of clamp connectors ensures a tight and secure fit on battery terminals, which minimizes the risk of accidental disconnections while the vehicle is in operation. This secure connection is crucial for maintaining a stable power supply to the vehicle’s electrical system.

- Durability: Made from robust materials, clamp connectors are built to withstand the harsh conditions often found in automotive environments, including temperature fluctuations and exposure to moisture. Their durability helps prevent corrosion, which can impede electrical performance over time.

- Compatibility: Clamp connectors are available in various sizes and styles, making them compatible with a wide range of vehicle battery types and terminal configurations. This versatility allows users to find the right fit for their specific vehicle without needing to purchase specialized components.

- Cost-Effectiveness: Generally, clamp connectors are affordable options compared to other types of battery connectors. Their widespread availability and competitive pricing make them an attractive choice for consumers looking to maintain or replace their car battery connections without overspending.

What Key Features Should You Consider When Choosing Car Battery Connectors?

When choosing car battery connectors, several key features should be considered to ensure optimal performance and safety.

- Material Quality: The material of the connectors can significantly affect conductivity and corrosion resistance. Copper connectors are preferred for their excellent conductivity, while lead connectors are more affordable but may corrode faster, leading to poor performance.

- Size and Compatibility: It’s essential to select connectors that fit your car’s battery terminals securely. Check the gauge of the cables and the terminal type (top post or side post) to ensure compatibility and prevent any loose connections that could lead to electrical failures.

- Insulation: Good insulation helps prevent short circuits and protects against environmental factors. Look for connectors with quality insulation materials, such as rubber or heat shrink tubing, which can withstand high temperatures and harsh conditions.

- Ease of Installation: Some connectors come with user-friendly designs that make installation simpler, such as quick-release features or color-coded terminals. Choosing connectors that are easy to install can save time and reduce the risk of improper connections.

- Current Rating: The current rating of the connectors should match or exceed the requirements of your vehicle’s electrical system. Select connectors that can handle the necessary amperage to ensure reliable power delivery and prevent overheating.

- Durability: Durability is crucial for connectors that will be subjected to vibrations and harsh weather. Look for connectors that are designed for heavy-duty use, with reinforced structures that can withstand wear and tear over time.

- Brand Reputation: Opt for connectors from reputable brands known for their quality and reliability. Established manufacturers often provide warranties and have a history of positive customer feedback, which is important for long-term satisfaction.

How Important Is the Gauge Size for a Car Battery Connector?

The gauge size of a car battery connector is crucial for ensuring optimal electrical conductivity and safety in the vehicle’s electrical system.

- Wire Gauge Size: The wire gauge size, typically measured in American Wire Gauge (AWG), determines the thickness of the wire used in battery connectors. Thicker wires (lower AWG number) can carry more current without overheating, making them essential for high-performance applications or larger vehicles.

- Current Rating: Each gauge has a specific current rating, which indicates the maximum amount of electrical current that can safely pass through the connector. Choosing a connector with an appropriate gauge size ensures it can handle the vehicle’s starting and accessory load without risk of failure or damage.

- Resistance: The gauge size also affects the electrical resistance of the connectors. Lower resistance in thicker wires minimizes energy loss and voltage drop, leading to better vehicle performance, especially during engine start-up when high current is required.

- Connection Stability: Proper gauge sizing enhances the stability of the connection between the battery and the vehicle’s electrical system. A connector that is too thin may lead to loose connections over time, resulting in poor performance and increased wear on electrical components.

- Safety Considerations: Using the correct gauge size is critical for safety; inadequate sizing can lead to overheating, melting insulation, and even electrical fires. It’s essential to adhere to manufacturer specifications for gauge size to ensure the longevity and safety of the vehicle’s electrical system.

Why Does Material Type Matter for Connector Performance?

According to a study published in the Journal of Electrical Engineering, copper connectors outperform aluminum in conductivity, enabling better power transfer and reducing energy loss (Smith et al., 2020). This is crucial in car battery applications where efficient energy transfer is essential for starting the engine and powering electrical systems.

The underlying mechanism revolves around the physical properties of the materials. Copper has a lower resistivity compared to aluminum, which means it allows electricity to pass through more easily, resulting in less heat generation and a lower likelihood of connection failures. Moreover, copper is less prone to oxidation than aluminum, which can degrade performance over time. When connectors corrode, they increase resistance at the connection point, leading to poor battery performance and potential starting issues (Johnson, 2019).

Additionally, the mechanical properties of the materials also play a role in connector performance. For instance, copper connectors can withstand higher mechanical stress than aluminum, ensuring a more secure and stable connection even under vibration and temperature fluctuations typical in an automotive environment. This durability is essential for maintaining a reliable electrical connection over the lifespan of the vehicle.

What Benefits Can Upgrading Your Car Battery Connectors Provide?

Upgrading your car battery connectors can significantly enhance your vehicle’s electrical performance and reliability.

- Improved Electrical Conductivity: Upgraded connectors often feature higher-quality materials, such as copper or gold plating, which provide superior conductivity. This results in less voltage drop, ensuring that more power reaches the starter and other electrical components efficiently.

- Enhanced Durability: High-quality battery connectors are designed to withstand extreme temperatures and environmental conditions. This durability prevents corrosion, cracking, or breakage, which can lead to battery failures and costly repairs.

- Better Fit and Connection: Upgraded connectors typically offer a more secure fit, reducing the likelihood of loose connections. A tight connection minimizes arcing and resistance, leading to better overall performance and longevity of the battery.

- Increased Safety: Quality connectors often come with features such as insulated covers and designs that prevent accidental short circuits. This added safety reduces the risk of electrical fires and enhances the overall safety of your vehicle’s electrical system.

- Improved Aesthetic Appeal: Many upgraded battery connectors come in various colors and finishes, allowing for a more visually appealing installation. A well-dressed battery can enhance the overall look of the engine bay, particularly for car enthusiasts who value aesthetics.

How Can Improved Connectors Enhance Electrical Efficiency?

Improved connectors can significantly enhance electrical efficiency in automotive applications, particularly in relation to car batteries.

- Material Quality: High-quality materials such as copper or gold-plated connectors reduce resistance and improve conductivity. This ensures minimal energy loss during transmission, which can lead to better overall performance of the vehicle’s electrical system.

- Design and Fit: Connectors designed for a snug and secure fit prevent arcing and overheating. A tight connection ensures that the flow of electricity is consistent and reduces the likelihood of corrosion, which can negatively impact efficiency over time.

- Corrosion Resistance: Connectors with anti-corrosive coatings or treatments extend the lifespan of the connection points. By preventing corrosion, these connectors maintain optimal electrical flow, which is crucial for the reliability of the vehicle’s starting and charging systems.

- Ease of Installation: User-friendly designs that allow for easier installation can improve maintenance practices. When connectors are easy to use, it encourages regular checks and replacements, ensuring that the electrical system remains in top condition.

- Current Rating: Connectors with higher current ratings can handle increased electrical loads without overheating. This is particularly important for vehicles with advanced electrical systems that require more power, ensuring that the battery and other components function efficiently.

What Safety Features Should Your Car Battery Connectors Have?

When selecting the best car battery connectors, several important safety features should be considered to ensure reliable performance and prevent accidents.

- Insulated Handles: Insulated handles on battery connectors prevent accidental electrical shocks when connecting or disconnecting batteries. This feature is especially crucial for users who may not be familiar with battery maintenance, ensuring safety during operation.

- Corrosion Resistance: Battery connectors made from materials that resist corrosion, such as brass or lead, significantly enhance their longevity and performance. Corrosion can lead to poor electrical connections and potential failures, making it essential for connectors to withstand harsh environments.

- Secure Locking Mechanism: A secure locking mechanism ensures that connectors stay firmly attached to the battery terminals, reducing the risk of disconnection while driving. This feature promotes stable electrical connections and prevents short circuits, which can cause damage or pose safety hazards.

- Gold-Plated Contacts: Gold-plated contacts provide superior conductivity and resistance to oxidation compared to standard connectors. This ensures a stable power supply and reduces the likelihood of connection failures due to poor conductivity over time.

- Heat Resistance: Car battery connectors that can withstand high temperatures are critical for preventing melting or deformation during operation. This feature is particularly important in hot climates or under heavy load conditions, where overheating could lead to dangerous situations.

- Visual Indicators: Some battery connectors come with visual indicators that show whether the connection is secure or if the battery is charging. These indicators can help users quickly assess battery status, enhancing the ease of use and safety during maintenance.

How Do You Properly Install and Maintain Car Battery Connectors to Ensure Longevity?

To ensure longevity in car battery connectors, proper installation and maintenance practices are essential. Follow these steps for optimal results:

-

Cleaning Connection Points:

– Before installation, clean the terminals of the battery and connectors with a mixture of baking soda and water to neutralize any corrosion. Rinse and dry thoroughly. -

Secure Connections:

– Install the positive connector (red) first, followed by the negative connector (black). Ensure the connectors are snug and properly seated to prevent arcing or loosening. -

Apply Anti-Corrosion Grease:

– Use a thin layer of petroleum jelly or specialized anti-corrosion grease on the connectors to protect against moisture and corrosion. -

Regular Inspections:

– Periodically check connections for any signs of corrosion or looseness. Tighten connections as needed and clean any buildup to ensure good electrical conductivity. -

Monitor Battery Health:

– Be aware of the battery’s performance. A declining charge could indicate a need for connector replacement or further inspection.

Maintaining your car battery connectors through proper installation and regular checks can significantly extend their lifespan and enhance overall vehicle performance.

Related Post: