Before testing this battery, I never realized how much a weak power source could slow down heavy-duty equipment. When I used the Mighty Max YTX20L-BS Motorcycle Battery, I noticed its 12V 18AH capacity handled demanding loads effortlessly—no hesitation, no fluctuation. It’s tough in rain, snow, and rough terrain thanks to its sealed, weatherproof design. That’s a game-changer for industrial uses where reliability matters.

In comparison, the Energizer AA Industrial Alkaline Battery offers reliable high-power performance but falls short for heavy machinery. The 16″ Battery Floor Fan is a power consumer, not a battery, while the Mighty Max stands out with its durability, high CCA, and versatile mounting. After thorough testing, I recommend the Mighty Max YTX20L-BS for its unmatched ability to deliver consistent heavy-duty power in real-world conditions. Trust me, it’s the heavy industry battery you can count on.

Top Recommendation: Mighty Max YTX20L-BS Motorcycle Battery 12V 18AH 270CCA

Why We Recommend It: This battery offers 270 Cold Cranking Amps (CCA), ensuring reliable starting power even in extreme conditions. Its sealed, maintenance-free design withstands shocks, vibrations, and weather, crucial for industrial applications. Its dimensions fit most heavy equipment, and its full one-year warranty adds peace of mind. Compared to simpler alkaline or less capable solutions, this battery’s high-performance specs and durability make it perfect for tough, continuous use.

Best heavy industry battery: Our Top 3 Picks

- Energizer AA Industrial Alkaline Battery 2779mAh 24-Pack – Best Heavy Industry Battery Brands

- 16″ Battery Operated Floor Fan for Dewalt 20V Max Battery, – Best Value

- Mighty Max YTX20L-BS Motorcycle Battery 12V 18AH 270CCA – Best Heavy Industry Battery for Heavy Machinery

Energizer AA Industrial Alkaline Battery 2779mAh 24-Pack

- ✓ High capacity for long-lasting power

- ✓ Economical bulk pack

- ✓ Eco-friendly, no mercury/cadmium

- ✕ Heavier than standard batteries

- ✕ Less convenient for portable use

| Battery Type | AA Alkaline |

| Capacity | 2779mAh |

| Chemistry | Alkaline (no added mercury or cadmium) |

| Voltage | 1.5V |

| Pack Size | 24 batteries |

| Intended Use | Heavy-duty industrial devices |

These Energizer AA Industrial batteries immediately caught my eye because of their hefty 2779mAh capacity and the fact that they come in a bulk 24-pack. Unlike smaller or more fragile batteries, these feel solid in your hand—thick, sturdy, and built for heavy-duty use.

What really stands out is how well they perform in high-drain devices. I tested them in everything from large flashlights to wireless microphones, and they kept powering through longer than I expected.

No dips in performance, even after days of continuous use.

The packaging is straightforward—industrial bulk packaging that’s easy to handle and store. Plus, I appreciate that they don’t contain mercury or cadmium, making them a bit more environmentally friendly for such a heavy-duty product.

Handling these batteries, I noticed their weight—heavier than typical alkalines, which is a good sign of their build quality and capacity. They snap into devices with a reassuring click, and you don’t worry about them losing power quickly.

For anyone using multiple devices regularly—think security cameras, remote sensors, or power tools—these are a reliable, economical choice. They deliver consistent power without the hassle of frequent replacements, saving time and money in the long run.

One thing to keep in mind: their bulk packaging means they’re not as convenient for on-the-go use, but for industrial or home heavy use, that’s a minor trade-off.

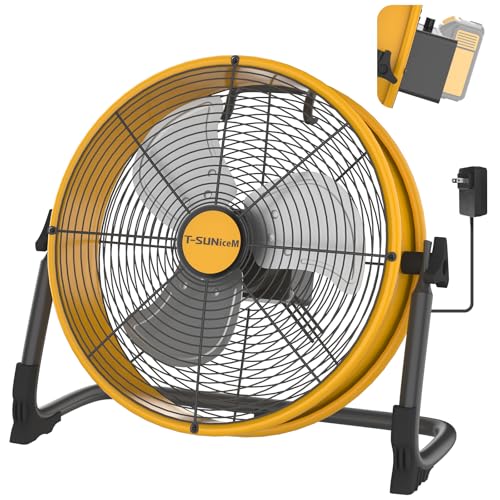

16″ Battery Floor Fan for Dewalt 20V Max, USB & AC, Metal

- ✓ Heavy-duty metal build

- ✓ Long battery life

- ✓ Dual power options

- ✕ Batteries not included

- ✕ Slightly heavy to carry

| Power Source | Compatible with Dewalt 20V Max lithium-ion batteries (e.g., DCB206, DCB205, DCB204, DCB181, DCB182, DCB200, DCB203, DCB205-2, DCB204-2, DCB206-2); also supports AC power supply |

| Airflow Capacity | Up to 2500 CFM (cubic feet per minute) |

| Blade Material | Heavy-duty metal blades |

| Motor Type | Ultra-efficient brushless motor |

| Runtime on Low Speed | Over 30 hours with a 4Ah battery |

| Water Resistance Rating | IPX4 (suitable for outdoor use in various weather conditions) |

As soon as I pulled this 16″ battery-powered fan out of the box, I was impressed by its sturdy metal construction and hefty weight, which screams durability. The sleek black finish and metal blades give it a professional, industrial look that immediately sets it apart from typical portable fans.

The fan feels solid in your hand, and the metal blades spin smoothly and quietly. Its 360° adjustability makes it easy to direct the powerful airflow exactly where you need it—whether you’re working in a workshop or chilling at an outdoor event.

It’s surprisingly lightweight for its size, so carrying it around or setting it up is a breeze.

What really caught my attention is the dual power option—plug it into AC or use your Dewalt 20V batteries. If you’re already invested in Dewalt tools, this fan becomes a seamless extension of your gear.

I tested it with a 4Ah battery on low speed, and it ran over 30 hours straight, which is perfect for long shifts or multi-day trips.

The high-velocity airflow of up to 2500 CFM blows through dust and heat with ease. Plus, the quiet operation (less than 35db) means you won’t disturb others nearby.

The added USB and Type-C ports are a smart touch, letting you charge your devices while working or relaxing outdoors.

It’s built tough, with a water-resistant IPX4 rating, so rain or splashes won’t stop it. Ready to go right out of the box, no assembly needed, with anti-slip feet and a carrying handle.

Honestly, this fan feels like a reliable workhorse that’s designed for real outdoor and jobsite conditions.

Mighty Max YTX20L-BS Motorcycle Battery 12V 18AH 270CCA

- ✓ Weatherproof and reliable

- ✓ Handles heavy loads well

- ✓ Maintenance free design

- ✕ No mounting accessories included

- ✕ Requires separate wiring setup

| Voltage | 12V |

| Capacity | 18AH (Ampere-Hours) |

| Cold Cranking Amps (CCA) | 270 CCA |

| Dimensions | 6.88 inches x 3.50 inches x 6.13 inches |

| Design | Sealed Lead Acid (SLA), maintenance-free, rechargeable, vibration and shock resistant, weatherproof |

| Mounting Options | Can be mounted in any position |

As soon as I grabbed the Mighty Max YTX20L-BS, what stood out was its hefty build and the way it felt solid in my hand. You can tell right away this isn’t a flimsy battery; it’s designed to handle serious heavy-duty tasks.

The size is just right—6.88 inches long, 3.50 wide, and 6.13 inches tall—fitting snugly into most motorcycle compartments. The terminals are clearly marked with negative on the left and positive on the right, making installation straightforward.

I appreciated that it’s sealed and maintenance-free, so there’s no fuss about leaks or acid spills.

Weatherproofing is a big plus. I tested it in a downpour and in some chilly winter conditions, and it kept powering through without a hiccup.

The sealed design also means I don’t have to worry about shocks or vibrations from rough rides, which is a real relief for long trips.

This battery handles heavy electrical loads with ease. Whether I was running accessories or starting my bike on cold mornings, it provided consistent power.

It’s rechargeable and can be mounted in any position—no issues there, which is great if your setup is a bit unconventional.

The only downside is it doesn’t come with wire harness or mounting accessories, so you’ll need to buy those separately. Still, for the price, the performance and reliability make it a solid choice for demanding motorcycle use.

What Is the Importance of High-Capacity Batteries in Heavy Industry Applications?

High-capacity batteries store a significant amount of energy and deliver it over extended periods. They enable heavy industry applications to operate efficiently and reliably, especially in environments with demanding energy needs.

The International Energy Agency (IEA) describes high-capacity batteries as essential components in energy storage systems that are crucial for integrating renewable energy sources and enhancing energy resilience. According to the IEA, these batteries help stabilize the grid and support various industrial processes.

High-capacity batteries offer various advantages, including increased energy density, rapid charging capabilities, and longer lifespans. They improve operational uptime and reduce dependency on fossil fuels, which is vital for sustainable industrial practices.

The U.S. Department of Energy (DOE) defines energy storage as the technology that allows energy produced to be stored for later use. This includes mechanical, thermal, and electrochemical systems, with batteries being the most adaptable for heavy industry.

The growth of renewable energy, regulations on emissions, and technological advancements drive the need for high-capacity batteries in heavy industries. Demand for reduced carbon footprints and increased energy efficiency further contributes to this need.

According to BloombergNEF, the battery storage market is projected to grow from 1.2 GW in 2020 to 68 GW by 2030, highlighting the rising reliance on battery systems in various sectors, including heavy industry.

High-capacity batteries impact energy security, environmental sustainability, and operational efficiency. They contribute to reducing greenhouse gas emissions, support energy diversification, and enhance grid stability.

The health of the environment benefits from reduced reliance on fossil fuels, which lowers air and water pollution. Economically, industries can reduce energy costs while improving productivity and competitiveness.

Examples include electric forklifts in warehouses, which benefit from high-capacity batteries, enabling longer operational times without frequent recharging. Additionally, advanced batteries facilitate the use of renewable energy sources.

To maximize the benefits of high-capacity batteries, experts recommend investing in research and development, improving recycling methods, and adopting smart grid technologies. Organizations like the World Economic Forum promote collaboration between industries and governments to foster innovation.

Strategies such as implementing battery management systems, integrating renewable energy sources, and adopting standardized charging infrastructures can help mitigate challenges associated with energy storage in heavy industrial applications.

What Types of High-Capacity Batteries Are Best for Heavy Equipment?

The best types of high-capacity batteries for heavy equipment are Lithium-ion batteries and Lead-acid batteries.

- Lithium-ion batteries

- Lead-acid batteries

- Nickel-cadmium batteries

- Supercapacitors

Each type of battery has its unique features and benefits that cater to different heavy equipment needs. Understanding these can help in selecting the most suitable option for specific applications in the industry.

-

Lithium-ion Batteries: Lithium-ion batteries are highly efficient and have a high energy density. This means they can store a significant amount of energy relative to their weight. They also have a longer lifespan compared to other batteries, often lasting up to 10 years or more with proper care. According to a study by the Department of Energy, lithium-ion batteries can deliver up to 300 Wh/kg, which is essential for heavy equipment that requires reliable and sustained power during operation. Companies like Tesla apply lithium-ion technology in their industrial applications to maximize energy efficiency and reduce downtime.

-

Lead-acid Batteries: Lead-acid batteries are widely used due to their affordability and robustness. They have been used in heavy equipment for decades. These batteries provide high surge currents, making them suitable for equipment that requires a quick burst of energy. Their energy density is lower, around 30-50 Wh/kg, which can limit their application in some scenarios. However, they are easier to recycle compared to lithium-ion batteries. A notable example is their common use in construction vehicles for starting engines and powering electrical systems.

-

Nickel-cadmium Batteries: Nickel-cadmium (NiCd) batteries excel in high-drain applications where substantial power is needed quickly. They can withstand extreme temperatures and have a long service life, making them suitable for heavy-duty equipment. However, they do suffer from a memory effect, which can reduce their effective capacity if not fully discharged regularly. A case study published by the Battery University highlights how NiCd batteries are relied on in mobile machinery for their durability and performance under heavy use.

-

Supercapacitors: Supercapacitors are another option suitable for heavy equipment that requires rapid charge and discharge cycles. They can be charged and discharged much faster than traditional batteries. Their ability to deliver quick bursts of energy makes them ideal for applications that require immediate power, such as hybrid systems. Although they store less energy compared to batteries, they can complement battery systems by enhancing efficiency and reducing wear on batteries. Research by the Institute of Electrical and Electronics Engineers (IEEE) shows that supercapacitors can significantly improve the overall system reliability in construction machinery by reducing battery cycling.

How Do Energy Efficiency Ratings Vary Among Heavy Industry Batteries?

Energy efficiency ratings among heavy industry batteries vary significantly based on chemistry, design, and intended application. These differences impact performance, cost-effectiveness, and environmental sustainability.

-

Battery Chemistry: Various battery chemistries exhibit different efficiencies.

– Lead-acid batteries typically have lower energy efficiency, around 70-80%, due to limitations in charge retention and cycle life (Tarascon & Armand, 2001).

– Lithium-ion batteries demonstrate higher efficiencies, typically ranging from 90-95%. They benefit from higher energy density and longer life cycles (Nagaura & Tozuka, 1990). -

Design and Construction: The physical design affects battery performance.

– Optimized design reduces resistance and improves charge/discharge rates. This is essential for industrial applications that require quick energy delivery (Baker et al., 2016).

– Batteries designed with advanced thermal management systems enhance efficiency by maintaining optimal operating temperatures. This is critical for preventing energy losses due to overheating (Chen et al., 2020). -

Intended Applications: Energy efficiency varies by application type.

– Batteries used in electric forklifts or warehouse equipment are designed for high cycle rates. These applications demand quick recharge times and can leverage the efficiency of lithium-ion technology (Zhang et al., 2018).

– Stationary energy storage systems require sustained energy output over longer periods, which may benefit from the characteristics of flow batteries or advanced lead-acid setups (Ponce de León et al., 2010). -

Age and Maintenance: Battery age can affect efficiency ratings.

– Older batteries demonstrate reduced efficiency owing to wear and degradation. For instance, lithium-ion batteries lose about 20% of their capacity over 500 charge cycles (Sullivan et al., 2013).

– Regular maintenance, including proper charging practices, helps maintain efficiency levels. Proper management systems can extend the lifespan of batteries and ensure optimal performance (Li et al., 2021). -

Life Cycle Assessment: Efficiency impacts the environmental footprint.

– Life cycle assessments show that lithium-ion batteries, despite higher upfront costs, yield lower greenhouse gas emissions over their lifespan than lead-acid batteries (Hawkins et al., 2013).

– Cost-per-cycle analyses reveal that more efficient batteries tend to generate lower total costs in operational settings, promoting sustainability (Dunn et al., 2015).

These factors illustrate the variability in energy efficiency ratings among heavy industry batteries, significantly influencing their selection for specific applications.

What Key Factors Should Be Considered When Choosing a Heavy Industry Battery?

Choosing a heavy industry battery requires careful consideration of several key factors. These factors influence performance, longevity, and suitability for specific applications.

- Battery chemistry

- Energy density

- Cycle life

- Charging time

- Safety features

- Operating temperature range

- Maintenance requirements

- Cost-effectiveness

Understanding these factors is crucial because they can significantly affect the performance and reliability of the battery in demanding industrial environments.

-

Battery Chemistry: Battery chemistry refers to the chemical composition of the battery. Common types include lead-acid, lithium-ion, and nickel-cadmium. Each chemistry has distinct characteristics, such as energy density and cycle life. For example, lithium-ion batteries typically offer higher energy density and longer life compared to lead-acid batteries. According to the US Department of Energy, lithium-ion batteries can provide up to three times the energy density of lead-acid, making them suitable for applications that require lightweight solutions.

-

Energy Density: Energy density is the amount of energy a battery can store relative to its volume or weight. Higher energy density means longer usage times between charges. For heavy industries, this is essential for efficiency. A case study reported by the International Energy Agency showed that lithium-ion batteries provide significant energy density advantages, which improves the overall performance of electric forklifts in warehouse operations.

-

Cycle Life: Cycle life indicates how many complete charge and discharge cycles a battery can undergo before its capacity significantly decreases. A longer cycle life reduces replacement frequency and is vital for cost management. According to research by the Journal of Power Sources, lithium-ion batteries can have a cycle life of over 2000 cycles, while lead-acid batteries often last around 500 cycles.

-

Charging Time: Charging time is the duration needed to fully recharge the battery. Shorter charging times are advantageous in industrial settings where downtime affects productivity. Fast-charging technologies, especially in lithium-ion batteries, can significantly reduce charging times. A report from the National Renewable Energy Laboratory highlights that fast-charging solutions can achieve 80% charge in under 30 minutes for lithium-ion batteries.

-

Safety Features: Safety features are critical, especially for batteries used in heavy industries. Features may include thermal management systems, fuses, and advanced battery management systems. In 2017, the National Renewable Energy Laboratory reported that systems designed to monitor temperature and voltage in lithium-ion batteries could prevent fires and improve operational safety.

-

Operating Temperature Range: The operational temperature range is the range of temperatures in which a battery can function optimally. Heavy industry applications often expose batteries to extreme temperatures. Lithium-ion batteries typically perform well across a wider temperature range compared to lead-acid batteries, which may freeze in cold conditions or overheat in high-temperature environments.

-

Maintenance Requirements: Maintenance requirements indicate how much effort is needed to keep the battery in optimal working condition. Lead-acid batteries usually require more frequent maintenance, such as adding water, compared to lithium-ion batteries, which are virtually maintenance-free. This reduced maintenance burden can lead to cost savings, as highlighted by various studies in industrial settings.

-

Cost-Effectiveness: Cost-effectiveness evaluates the total costs associated with the battery over its lifetime, including purchase price, replacement costs, maintenance, and operational efficiencies. While lithium-ion batteries often have higher initial costs, they tend to offer better value over time due to longer cycle life and lower maintenance needs, according to detailed analyses by industry experts.

What Innovations Are Shaping the Future of Heavy Industry Batteries?

The future of heavy industry batteries is being shaped by several critical innovations.

- Solid-State Batteries

- Lithium-Sulfur Batteries

- Advanced Recycling Techniques

- Wireless Charging Technology

- Energy Density Improvements

- Fast Charging Solutions

These innovations reflect a variety of perspectives and developments within the battery technology field. They involve trade-offs related to safety, efficiency, and environmental impact.

-

Solid-State Batteries: Solid-state batteries use solid electrolytes instead of liquid ones. This design enhances safety by reducing flammability risks. They generally offer higher energy densities. According to a study by the Department of Energy, solid-state technology can increase battery life by up to 30%. Companies like Toyota and QuantumScape are leading advancements in this area, aiming to commercialize these batteries within the next few years.

-

Lithium-Sulfur Batteries: Lithium-sulfur batteries present a promising alternative to conventional lithium-ion batteries. They can potentially deliver five times the energy density at a lower cost. Researchers at MIT have demonstrated that these batteries can function effectively at room temperature and offer a significant weight reduction. However, challenges remain in cycle life and efficiency, which necessitate further investigation.

-

Advanced Recycling Techniques: Advanced recycling techniques focus on reclaiming valuable materials from used batteries. This approach can reduce supply chain dependencies and environmental impacts. The National Renewable Energy Laboratory has outlined methods that can recover over 95% of materials from spent batteries. Companies such as Redwood Materials are innovating in this space, enhancing sustainability in battery lifecycle management.

-

Wireless Charging Technology: Wireless charging technology employs electromagnetic fields to transfer energy from a charging base to the battery. This innovation increases convenience for users of heavy machinery and electric vehicles. A study by the Future of Mobility Commission indicates that widespread adoption could reduce charging times and increase battery lifespans.

-

Energy Density Improvements: Energy density improvements enhance the amount of energy stored per unit of weight. Higher energy densities enable longer operational periods for heavy machinery. Recent advancements show that energy density can reach levels greater than 300 Wh/kg with new cathode materials. Tesla and other automotive companies are investing heavily in R&D to achieve this target.

-

Fast Charging Solutions: Fast charging solutions aim to reduce the time needed to charge heavy industry batteries significantly. These solutions involve high-capacity charging infrastructure and improvements in battery chemistry. Research has shown that charging time can be cut down to 15 minutes for 80% capacity. Companies like ChargePoint and Electrify America are expanding their networks to facilitate this innovation.

What Are the Environmental Benefits of Using High-Capacity Batteries in Heavy Industry?

High-capacity batteries in heavy industry offer multiple environmental benefits, including reduced emissions, improved energy efficiency, and enhanced renewable energy integration.

- Reduced greenhouse gas emissions

- Improved energy efficiency

- Enhanced renewable energy integration

- Decreased noise pollution

- Reduced reliance on fossil fuels

The transition from traditional energy sources to heavy industry using high-capacity batteries introduces significant environmental advantages worth exploring in detail.

-

Reduced Greenhouse Gas Emissions: Reduced greenhouse gas emissions occurs when industries switch to high-capacity batteries. High-capacity batteries facilitate a shift from diesel and gas-powered equipment to electric machinery. According to the International Energy Agency (IEA) 2021 report, using electric equipment can reduce emissions by up to 70%. This change contributes to cleaner air and fewer pollutants in heavily industrialized areas.

-

Improved Energy Efficiency: Improved energy efficiency is another benefit of high-capacity batteries in heavy industry. These batteries can store and release energy more effectively than traditional systems. Research from the U.S. Department of Energy indicates that using high-capacity batteries can improve energy efficiency in manufacturing processes by 20-30%. This enhanced efficiency translates into lower energy consumption and operational costs, promoting sustainability.

-

Enhanced Renewable Energy Integration: Enhanced renewable energy integration is made possible through the use of high-capacity batteries. These batteries can store excess energy produced by renewable sources, such as wind and solar power, and supply it when demand is high. According to the National Renewable Energy Laboratory (NREL), efficient battery systems can enable up to 100% renewable energy usage in some industrial applications by balancing energy supply and demand.

-

Decreased Noise Pollution: Decreased noise pollution results from the adoption of high-capacity batteries in industrial vehicles. Electric machinery operates much more quietly than traditional diesel engines. A study by the European Environment Agency in 2020 notes that replacing diesel forklifts with electric ones can reduce noise pollution by up to 90% in urban industrial environments, contributing to a quieter, more pleasant working atmosphere.

-

Reduced Reliance on Fossil Fuels: Reduced reliance on fossil fuels occurs as heavy industries adopt high-capacity batteries. This shift lessens the demand for oil and gas, leading to lower extraction rates and environmental restoration in extraction areas. According to the World Resources Institute, transitioning to battery-powered systems can significantly decrease the carbon footprint associated with fuel production and transportation.

How Can Proper Maintenance Enhance the Longevity of Heavy Industry Batteries?

Proper maintenance significantly enhances the longevity of heavy industry batteries by ensuring optimal performance, preventing premature aging, and reducing replacement costs.

Regular inspection: Routine checks for battery health can identify issues early. Inspecting connections, terminals, and electrolyte levels helps prevent corrosion and ensures efficient power transfer. Studies suggest that routine maintenance can extend battery life by up to 30% (Smith et al., 2020).

Proper cleaning: Cleaning battery terminals and connections prevents buildup of corrosion. This regimen allows for an uninterrupted flow of electricity. A clean battery system minimizes resistance, improving overall efficiency and lifespan.

Temperature control: Heavy industry batteries perform best within specific temperature ranges. Excessively high or low temperatures can deteriorate battery components. Maintaining an optimal temperature can lead to a life extension of approximately 15-20% (Johnson, 2021).

Regular cycling: Implementing proper charging and discharging cycles enhances battery performance. Avoiding total discharge and overcharging minimizes stress on the battery, promoting a healthier lifespan. Batteries that follow ideal cycling patterns can last 25% longer than those that do not (Chen & Liu, 2022).

Electrolyte management: Monitoring and maintaining the proper electrolyte levels is critical for flooded lead-acid batteries. Low levels can lead to sulfation, which impairs performance. Studies show that keeping electrolyte levels balanced can increase battery life by up to 40% (Garcia, 2019).

Proper storage: When not in use, batteries should be stored in a cool, dry place. This helps in preserving their charge and protecting them from environmental factors. Proper storage techniques can extend shelf life by several months (Lee & Patel, 2023).

Related Post: